Risk Mitigation Through Coal Conveying Vibrators

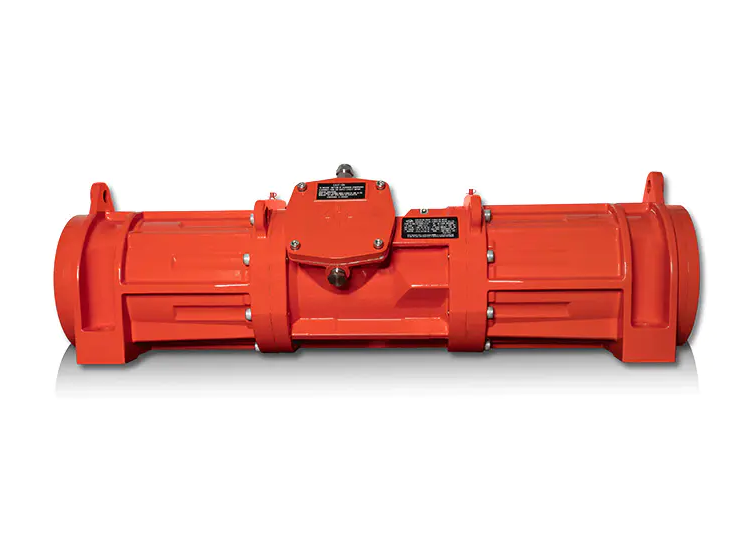

Operational safety in a coal plant is as important as efficiency. One of the hidden enablers of safer material handling is the use of a Coal Plants Vibrator and Coal Conveying Vibrator. These devices, when properly implemented, can significantly reduce the risks associated with material hang-ups, bridging, and manual clearing.

Coal stored in bunkers or silos can compact over time, especially under pressure and moisture. This compaction can lead to bridging, where the bulk material forms a stable arch that prevents flow. When this happens, workers are often required to manually dislodge the coal, which can be hazardous due to dust, falling material, and confined space risks. By employing a Coal Plants Vibrator, vibration energy continuously agitates the material, preventing compacted bridging and eliminating many manual interventions.

Along conveyor lines, hanging material at transfer chutes or loading points can create unstable lumps that dislodge unpredictably. This presents a risk of sudden coal surges, potential spillage, or even damage to equipment. Integrating a Coal Conveying Vibrator at sensitive points helps dislodge these lumps under controlled conditions, keeping flow steady and predictable.

Using vibration not only reduces the physical risk to personnel but also mitigates mechanical risk. For example, when coal suddenly dislodges, it can overload conveyor belts or impact chutes. A vibrating system smooths out flow, lowering the likelihood of shock loads that might damage belt supports or cause material to spill.

Furthermore, vibration systems can be designed with feedback and monitoring. By measuring vibration amplitude, frequency, or current draw, operators can detect when the performance of the vibrators drifts, which may indicate wear or mounting issues. This kind of proactive monitoring, especially for a Coal Plants Vibrator, helps prevent failures that could escalate into safety incidents.

Selecting a reliable vibration motor supplier is essential. Shenzhen Putian Vibration Motor Co., Ltd. offers motors tailored for industrial duty, designed to maintain consistent performance in dusty, high-load coal plant environments. Their products support robust mounting, adjustable force, and long service intervals, making regular maintenance easier and safer.

In conclusion, by installing both a Coal Plant Vibrator inside storage bins and a Coal Conveying Vibrator along conveyor paths, coal plants can significantly improve operational safety. Reducing the need for manual clearing, smoothing material flow, and enabling continuous monitoring all contribute to a lower-risk working environment.