Enhancing Automotive Lighting Production with Auto Lamp Moulds

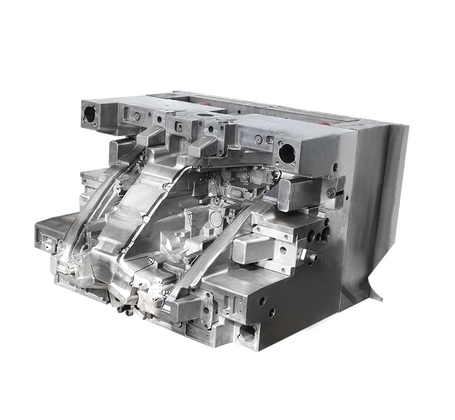

The automotive industry relies heavily on precise and reliable components to ensure safety, functionality, and aesthetics. Among these components, auto lamp systems play a crucial role. Producing these lamps requires careful attention to detail, and the quality of the mould used can significantly influence the outcome. Auto lamp moulds are specialized tools designed for the injection moulding process, allowing manufacturers to create intricate plastic lamp components efficiently.

The design of an auto lamp mould must account for complex geometries and optical clarity. Modern lamps often combine multiple lenses, reflectors, and housing structures, all of which require careful moulding to maintain performance standards. Using advanced computer-aided design software, engineers can simulate material flow, cooling rates, and potential stress points before manufacturing the mould. This process reduces errors and shortens production cycles.

Material selection is another critical factor in auto lamp moulding. Thermoplastics such as polycarbonate are frequently used due to their transparency, impact resistance, and heat tolerance. The mould must accommodate these materials, ensuring consistent thickness and minimal distortion during cooling. Any variation can affect the lamp's optical properties, compromising safety and functionality.

Production efficiency is closely linked to mould design. Well-engineered auto lamp moulds allow for faster cycle times, uniform component quality, and minimal maintenance. Regular inspections and adjustments are essential to maintain consistency, particularly in high-volume manufacturing settings.

Sustainability has become a consideration in auto lamp moulding. Optimizing material usage and reducing defects help lower the environmental impact of manufacturing. Some manufacturers also explore recyclable plastics or incorporate design features that simplify disassembly and recycling of automotive lamps.

Overall, auto lamp moulds represent a combination of engineering precision, material science, and manufacturing expertise. Their development requires attention to detail at every stage, from design and prototyping to full-scale production.