The Sustainable Choice: Reduce Your Worksite Waste by 70% with Our Drill System

Sustainability is no longer a buzzword; it's a business imperative and a collective responsibility. The construction and manufacturing industries are major contributors to global waste, and a significant portion of that comes from discarded tools and consumables. At Replaceable Alloy Drill, we believe in a future where high performance and environmental stewardship go hand in hand.

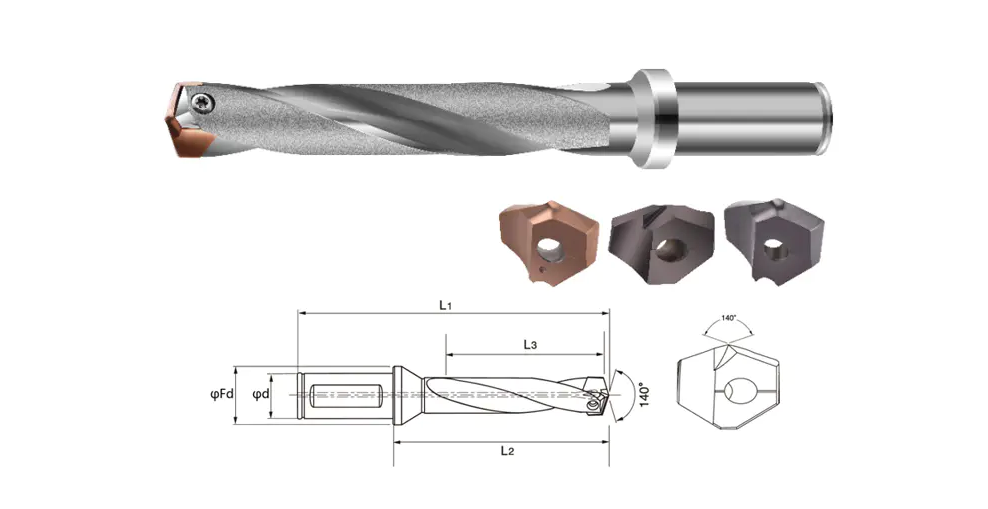

The traditional model of "drill-break-replace" is inherently wasteful. Millions of drills, with their metal housings, electronic components, and cables, end up in landfills every year, all because a few inches of the cutting tip are worn out. Our system directly addresses this problem. By designing a drill with a long-life body and a replaceable tip, we reduce material consumption by over 70% per replacement cycle.

This "reduce and reuse" model has a profound environmental impact. Less raw material needs to be mined, processed, and transported. The energy-intensive manufacturing process for a full drill is avoided with every tip you replace instead of a whole unit. Furthermore, we have established a tip-recycling program, ensuring that the valuable tungsten and cobalt in our used alloy tips are recovered and reintroduced into the manufacturing stream.

Choosing the Replaceable Alloy Drill is more than a purchasing decision; it's a vote for a circular economy and a sustainable workflow. It allows companies and individuals to significantly lower their carbon footprint and waste output without sacrificing an ounce of performance. Be part of the solution. Build a better, greener project with the tool designed for a better, greener planet.