Automotive Leaf Spring Market Expansion Driven by Lightweight Material Adoption 2030

Global Automotive Leaf Spring Market Overview (2024–2030)

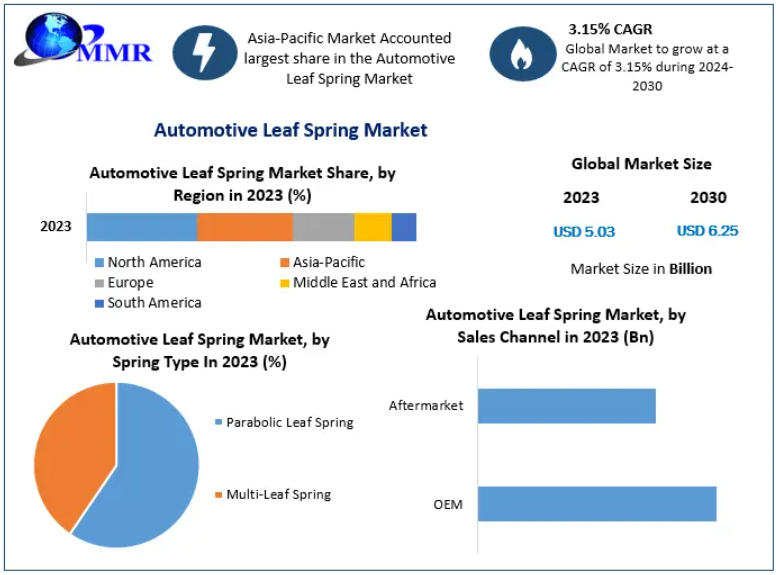

The Global Automotive Leaf Spring Market is projected to reach US$ 6.25 billion by 2030, growing at a CAGR of 3.15% during the forecast period. The market, valued at US$ 5.03 billion in 2023, continues to play a vital role in the automotive suspension system industry, particularly within commercial and passenger vehicles. Leaf springs, essential for supporting vehicle loads and absorbing road shocks, remain a key component in vehicles that demand strength, reliability, and cost-effectiveness.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/21179/

Market Dynamics

1. Growth Drivers

Rising disposable income, robust economic growth, and the expansion of industrial and logistics sectors have fueled the production of light, medium, and heavy commercial vehicles worldwide. The growing preference for quality automotive components that ensure durability and lower maintenance costs is propelling the demand for advanced leaf spring systems.

Additionally, the increasing availability of automobile financing options has expanded global vehicle sales, boosting demand for both OEM and aftermarket leaf springs. The surge in global vehicle fleet size, particularly for light and heavy commercial vehicles, continues to generate substantial aftermarket demand.

2. Market Challenges

However, geopolitical instability, economic volatility, and civil unrest—particularly across parts of the Middle East and Africa (MEA)—are expected to hamper regional market expansion. Raw material price fluctuations and the slow adoption of advanced composites in certain regions may also restrain growth to some extent.

3. Opportunities

The growing shift toward lightweight composite materials offers immense growth potential for market players. Composite leaf springs, known for their strength-to-weight ratio and corrosion resistance, are increasingly being adopted by OEMs seeking to enhance vehicle fuel efficiency and performance.

Segment Analysis

By Type of End:

-

Double End Leaf Springs dominate the market due to their wide application in light vehicles. These are fixed to the vehicle chassis at both ends, offering enhanced stability and ride comfort.

-

Open End Leaf Springs are primarily used in heavy commercial vehicles, providing better load-bearing capacity and durability under high-stress conditions.

By Spring Type:

-

Parabolic Leaf Springs are gaining rapid traction owing to their tapered design that ensures smoother ride quality and reduced inter-leaf friction. Their lightweight and efficiency make them an emerging choice among OEMs.

-

Multi-Leaf Springs, the traditional choice, continue to hold a significant share, especially in heavy-duty applications where load-bearing strength is paramount.

By Sales Channel:

-

OEMs contribute the majority of market share, driven by vehicle manufacturers' focus on improving ride comfort and suspension performance.

-

Aftermarket demand is supported by the aging vehicle fleet and growing replacement needs in developing economies.

By Vehicle Type:

-

Commercial Vehicles account for a substantial market share, given their reliance on robust suspension systems for load management.

-

Passenger Vehicles are expected to witness steady growth, supported by rising personal vehicle ownership in emerging markets.

By Location Type:

-

Rear Suspension systems dominate the market as leaf springs are widely used for rear axle load-bearing in commercial vehicles.

-

Front Suspension adoption is comparatively limited but gaining interest in light-duty vehicle segments.

By Material Type:

-

Metallic Leaf Springs remain the industry standard due to their strength and cost-effectiveness.

-

Composite Leaf Springs, though a smaller segment, are expanding rapidly owing to their lighter weight and superior fatigue resistance.

By Manufacturing Process:

-

Shot Peening enhances fatigue strength and remains a preferred process in conventional metal leaf spring manufacturing.

-

Prepreg Layup is gaining adoption in composite leaf spring production for its precision and weight optimization benefits.

To know the most attractive segments, click here for a free sample of the report:https://www.maximizemarketresearch.com/request-sample/21179/

Regional Insights

Asia-Pacific leads the global market and is projected to retain its dominance through 2030. Countries like China, India, Japan, and South Korea are major contributors to the region’s growth. India, supported by government initiatives such as “Make in India”, is emerging as a key manufacturing hub for automotive components.

Europe holds a significant share, driven by a strong OEM base and focus on suspension innovation. The region’s emphasis on comfort, safety, and sustainability continues to shape demand.

North America maintains steady growth owing to its established automotive infrastructure and high commercial vehicle utilization.

Meanwhile, Latin America and the Middle East & Africa are expected to see gradual improvements in demand as industrialization and logistics activities expand.

Competitive Landscape

The global automotive leaf spring market is moderately consolidated, featuring both global leaders and regional manufacturers. Key players are focusing on expanding production capacities, investing in lightweight materials, and adopting innovative suspension technologies. Strategic partnerships and mergers are also common to enhance market presence.

Key Players Include:

-

Rassini

-

Hendrickson USA, L.L.C.

-

Sogefi S.p.A.

-

Jamna Auto Industries

-

Emco Industries

-

LITE FLEX

-

NHK Springs Co. Ltd.

-

Mubea

-

SGL Group

-

IFC Composite

-

Frauenthal Group

-

Olgun Çelik San.

-

Jonas Woodhead & Sons India Ltd.

-

Auto Steels

-

Kumar Steels

-

Mack Springs

-

Protopower Springs Pvt. Ltd.

-

Vikrant Auto Suspensions

-

Akar Tools Limited

Conclusion

The Automotive Leaf Spring Market is poised for steady growth driven by increasing vehicle production, aftermarket expansion, and innovations in composite materials. While economic challenges in certain regions may constrain growth, rising industrialization, government initiatives to boost manufacturing, and the global shift toward lightweight suspension components will continue to support market expansion through 2030.