xCell: The Expeditionary Manufacturing Revolution

Introduction

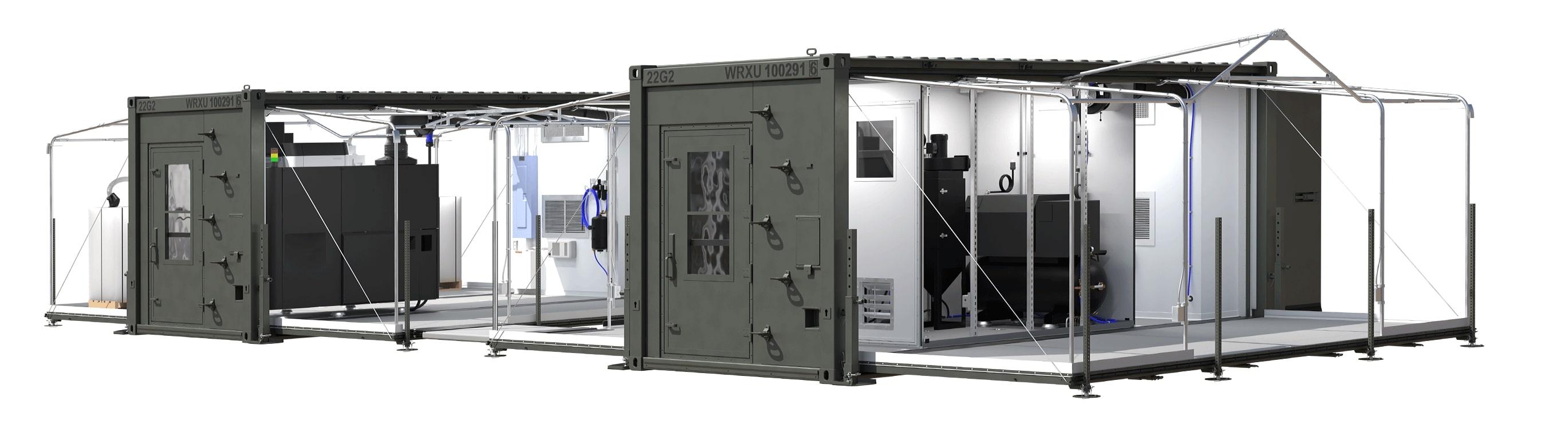

xCell is the breakthrough that has turned “we’re out of drones” into a phrase from the past. Developed by Firestorm Labs in San Diego, xCell is a fully containerized, off-grid manufacturing system that functions as a complete drone factory in one or two shipping containers. Capable of producing up to fifty Group 2 unmanned aerial systems per month with only one or two operators, xCell can be deployed anywhere and start generating mission-ready drones in hours. In an era where aerial attrition speed decides outcomes, xCell ensures that capability is never more than a day away—no matter how contested the environment.

The Strategic Imperative Behind xCell

Modern warfare has exposed the fatal weakness of centralized drone production. A single lost platform can take months and hundreds of thousands of dollars to replace while traveling vulnerable supply lines that adversaries target first. In peer conflict, that timeline is not a logistics problem; it is a defeat mechanism. In disaster zones, isolated communities wait days for aerial support that could save lives. xCell was created to eliminate both vulnerabilities by bringing production to the point of need instead of hoping the supply chain survives.

How xCell Works

xCell is built into standard twenty- or forty-foot ISO containers that blend into normal logistics flows and can be disguised as civilian cargo when required. Once on site it expands into a climate-controlled, generator-powered production cell equipped with multiple HP Multi Jet Fusion printers (Firestorm holds exclusive tactical deployment rights), robotic assembly arms, finishing stations, and AI-driven quality assurance. Onboard storage carries enough polymer powder for thirty to sixty days of continuous high-intensity operations.

A complete Tempest-class airframe can be printed, assembled, tested, and flown in nine to twenty-four hours. Critical spares—wings, motor mounts, payload bays—are produced in hours. Integration with Firestorm’s OCTRA avionics allows on-site mission configuration, from reconnaissance to electronic warfare, without depot support.

Real-World Validation

xCell has already proven itself in demanding conditions. In military exercises, it sustained drone detachments for weeks under complete logistics denial by printing replacements and repairs on demand. One trial restored a damaged platform with a new wing in under six hours—no external resupply required. The same system has printed mapping and medical-delivery drones in disaster simulations, showing its versatility extends to humanitarian missions.

Engineering the Hard Problems Away

Extreme heat, dust, and humidity are countered by ruggedized enclosures and real-time material calibration. Cyber threats are neutralized with air-gapped networks, encrypted transfer, and physical safeguards. Operator training is accelerated by Firestorm’s Warroom digital twin, which provides unlimited perfect flight hours before real hardware is ever touched.

Firestorm’s xCell represents the pinnacle of rapid drone production, turning forward operating locations into self-sustaining aerial regeneration nodes even when every traditional supply route has been severed.

The Path Forward

Firestorm continues to advance xCell with faster printing, expanded materials, and greater automation. Future versions will support networked operation for higher volumes, AI-optimized designs, and hybrid printing for larger platforms. Civilian applications—wildfire monitoring, search-and-rescue, medical logistics—are already demonstrating remarkable results.

Conclusion

xCell is more than equipment; it is a revolution in how aerial assets are sustained. Firestorm Labs has created a system that turns potential logistical weaknesses into enduring strengths. By enabling production at the point of need, xCell ensures operational continuity in the most challenging conditions, setting a new standard for resilience and adaptability in defense and humanitarian operations.

FAQs

-

What is xCell?

A deployable manufacturing system in shipping containers that produces drones and parts on-site. -

How fast can xCell produce a drone?

A complete airframe is typically ready in nine to twenty-four hours. -

Does xCell require ongoing resupply?

Only raw materials; one load supports thirty to sixty days of operations. -

Is xCell limited to specific designs?

No, its open architecture allows production of compatible airframes from various sources. -

Where is xCell used?

In military testing, operational deployments, and humanitarian simulations.