Regional Market Insights into Mechanical Tube Pipe Demand

Industrial and infrastructure developments worldwide continue to fuel the demand for mechanical tubes and pipes. These products are crucial for applications requiring high mechanical strength, pressure resistance, and durability. Industries such as automotive, oil and gas, manufacturing, and construction increasingly rely on mechanical tubes for structural, hydraulic, and fluid transport applications. Their ability to maintain operational reliability under stress has made them essential components in modern industrial ecosystems.

The Mechanical Tube Pipe Market benefits from widespread adoption across multiple sectors. Businesses refer to Mechanical Tube Pipe insights to understand industry trends, technological advancements, and emerging application areas. Access to such data enables manufacturers to optimize production, meet global quality standards, and anticipate shifts in regional consumption patterns.

In the automotive sector, mechanical tubes and pipes are used in fuel systems, hydraulic lines, and exhaust systems. Lightweight yet durable piping solutions enable vehicle manufacturers to improve fuel efficiency while maintaining structural integrity. Electric vehicle expansion further increases the adoption of high-performance piping materials due to stringent weight and performance requirements.

Construction and infrastructure projects also rely on mechanical tubes. They are employed in water distribution systems, heating and cooling networks, and structural applications where mechanical strength and corrosion resistance are essential. Rapid urbanization and infrastructure modernization projects continue to drive the demand for reliable and durable mechanical pipes.

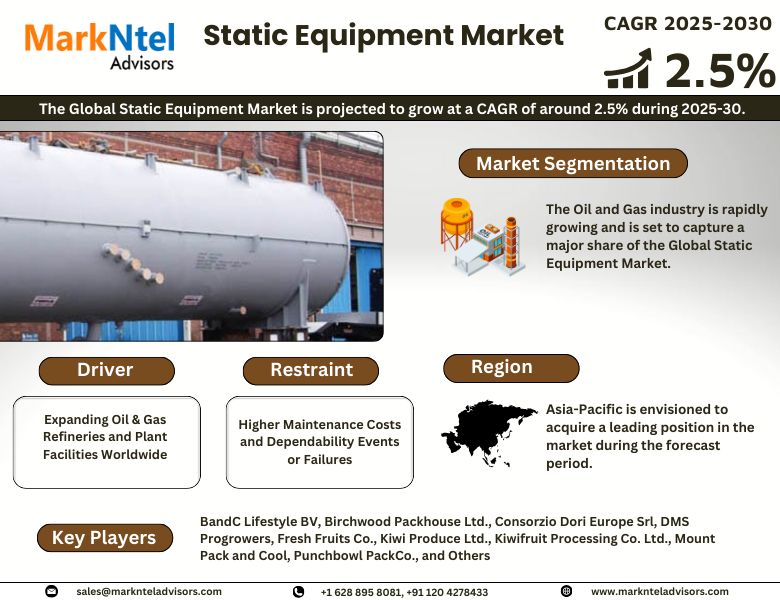

Oil and gas operations represent another key application area. Mechanical tubes are critical in drilling, refining, and pipeline transport processes. They must withstand high pressure, temperature variations, and chemical exposure. Continuous investment in energy infrastructure and exploration activities reinforces the adoption of robust piping systems.

Industrial machinery applications further fuel market expansion. Mechanical tubes are integral to hydraulic systems, fluid transport, and structural machinery components. Their wear resistance, dimensional stability, and flexibility allow manufacturers to reduce downtime and maintenance costs, ensuring smoother operations across industrial environments.

Sustainability trends are influencing production practices in the market. Manufacturers are increasingly focused on eco-friendly materials, energy-efficient production processes, and recycling initiatives. Compliance with global environmental regulations and growing client expectations for sustainable solutions enhance market attractiveness.

Regionally, Asia-Pacific leads due to its extensive industrial and automotive sectors. Europe focuses on technological innovation and high-quality manufacturing standards, while North America relies on advanced industrial machinery and infrastructure projects. Emerging markets are gradually increasing adoption as their industrialization progresses.

As industries modernize and production efficiency becomes more critical, the Mechanical Tube Pipe Market is set to continue its expansion. Companies that prioritize innovation, sustainability, and regional market strategies are well-positioned to capitalize on growing opportunities.