Step-by-Step: Production of a Rolling Kitchen Cart

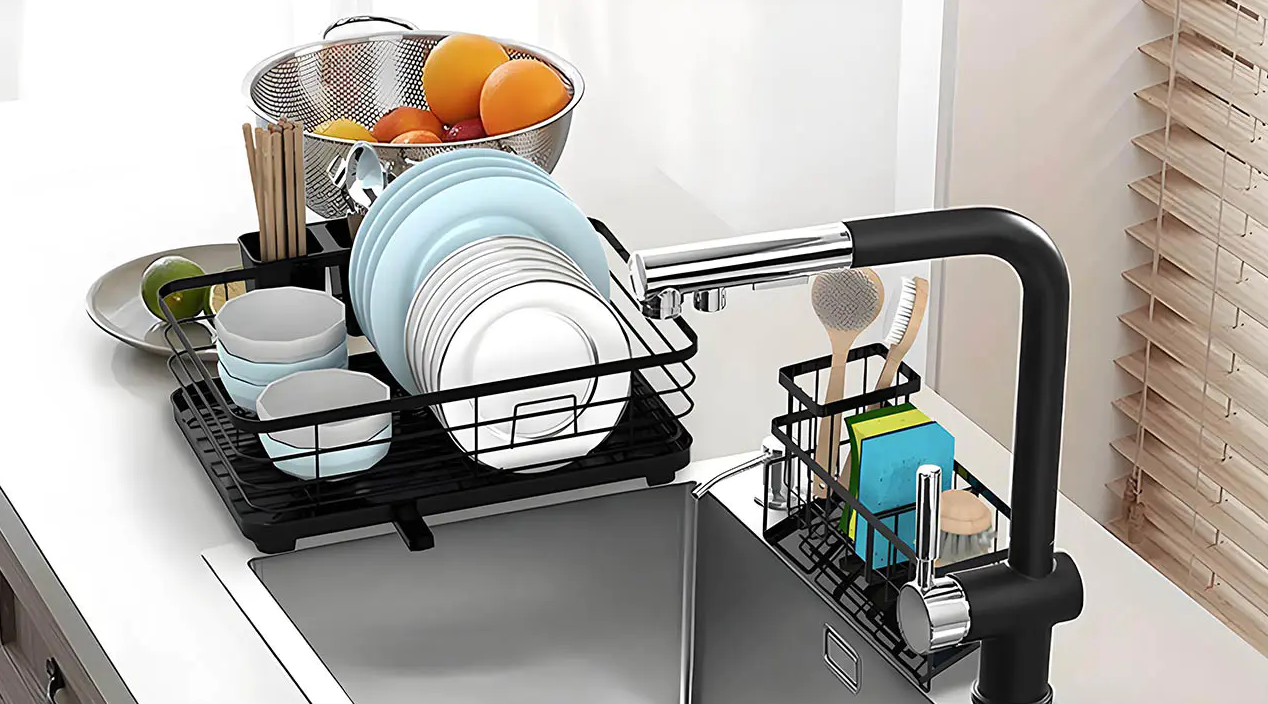

Have you ever wondered how a kitchen trolley comes to life? What does a Kitchen Trolley Manufacturer actually do behind the scenes? Today, we uncover the journey from concept to finished product by taking a close look at how Zhejiang Yacheng Industry and Trade Co., Ltd. builds these indispensable kitchen tools, and how they integrate a Kitchen Storage Rack into the design.

The process begins with design and planning. Engineers and product designers at Zhejiang Yacheng collaborate to create blueprints that balance utility, strength, and aesthetics. They consider load-bearing capacity, shelf layout, wheel design, and ease of assembly. The storage element is especially critical: deciding how many tiers the kitchen storage rack should have, how high each shelf should be, and how to reinforce them without adding unnecessary weight.

Once the design is finalized, materials are selected. Quality is important: steel tubing is commonly used for the frame to ensure stability, while shelf surfaces may be wire mesh, perforated metal, or even durable composite boards. The manufacturing facility sources these carefully, ensuring that structural integrity and finish standards meet the company’s expectations.

Following material procurement, the production moves to fabrication. Tubes are cut to length, bent, and welded. Shelves are stamped or molded, depending on the material. For trolleys, welding must be precise because the cart needs to support movement with weight. Poor welds could compromise both safety and longevity.

After the frame and shelves are ready, the focus shifts to finishing. Surfaces are treated — powder coating is often used for steel frames because it provides a protective layer that resists rust while giving a clean appearance. Shelves and racks are painted or coated in ways that are easy to clean and durable under frequent kitchen use.

Wheels (casters) are another critical part. Zhejiang Yacheng selects wheels that are smooth-rolling, lockable, and able to handle typical kitchen loads. These wheels are tested for friction, load, and wear to ensure long-term performance. The casters are then mounted to the frame, and each trolley is carefully balanced so it doesn’t wobble or tip when fully loaded.

After assembly, every unit undergoes quality control. Inspectors check weld points, shelf alignment, caster function, and overall stability. The kitchen storage rack portion is tested to make sure the tiers remain level and secure under weight. If any unit fails inspection, it's pulled aside for rework.

Following QC, the finished trolleys are packaged. Packaging is designed to protect corners and finishes during shipping, especially since these products are often exported worldwide. Zhejiang Yacheng, being an industrial trading company, ensures packaging is efficient and environmentally mindful, minimizing waste while protecting product integrity.

From the manufacturing plant to your kitchen, these trolleys go through logistics and distribution. The company coordinates transport, customs (if exported), and delivery. Once they arrive, customers can assemble them easily — many units come with tool-free designs or simple instructions.

To conclude, the life of a kitchen trolley — from the design table at Zhejiang Yacheng Industry and Trade Co., Ltd. to your kitchen — is a careful orchestration of engineering, material selection, craftsmanship, and quality control. The inclusion of a kitchen storage rack in these trolleys is not an afterthought; it’s a deliberate design choice that enhances value and utility. By understanding the manufacturing process, you can better appreciate the balance of form and function that goes into every rolling storage solution.