Why Regular Maintenance is Essential for #80 Chain Systems

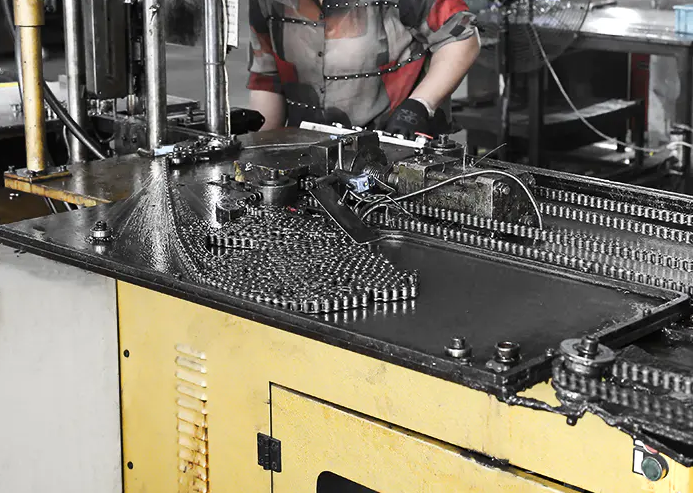

#80 Chains are an integral part of many industrial systems, offering reliability and strength for power transmission applications. However, like any mechanical component, #80 chains require proper maintenance to ensure long-term performance and avoid costly repairs or replacements.

The key to maintaining a #80 Chain is regular inspection and lubrication. Over time, friction and wear can cause the chain to lose its effectiveness, leading to breakdowns and system inefficiencies. By regularly inspecting the chain for signs of wear and tear, you can identify potential issues early and address them before they lead to costly failures.

Lubrication is also essential to keep the #80 chain running smoothly. Proper lubrication reduces friction, which in turn minimizes wear and prolongs the chain’s life. Regularly applying the right type of lubricant ensures that the chain operates efficiently and reduces the likelihood of corrosion, which can weaken the chain over time.

It is also important to ensure that the chain is properly tensioned. Over-tightening or under-tightening the chain can cause it to wear unevenly and lead to premature failure. Regular tension checks, along with adjustments as needed, will help extend the life of the #80 chain.

By following these simple maintenance tips, you can maximize the performance and longevity of your #80 chain. Working with reliable #80 Chain Manufacturers, such as Zhejiang Maigao Chain Industries Co., Ltd., ensures that you receive high-quality chains that are built to last, minimizing the need for frequent maintenance and reducing operational costs.